- Product Video

- Product Details

- Customer Case

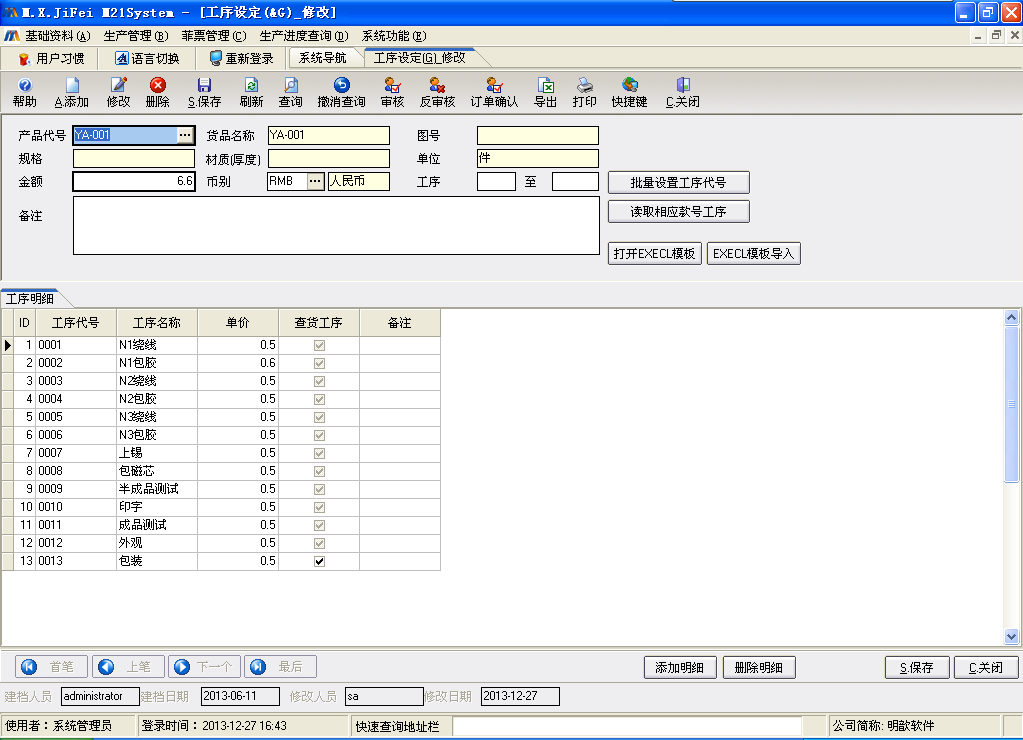

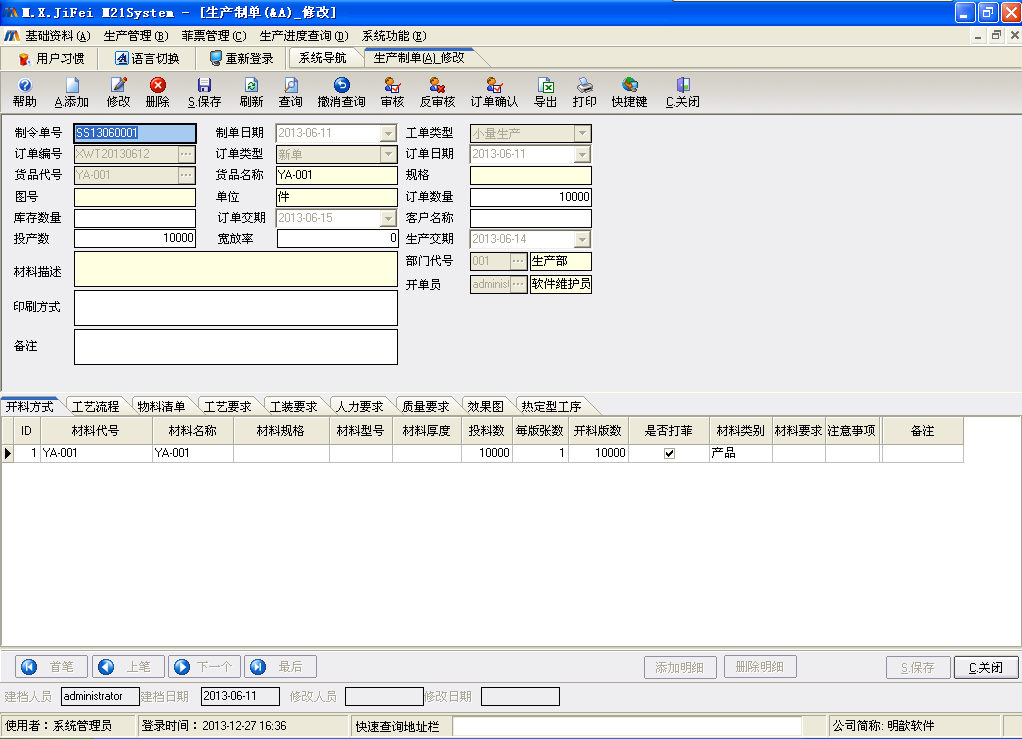

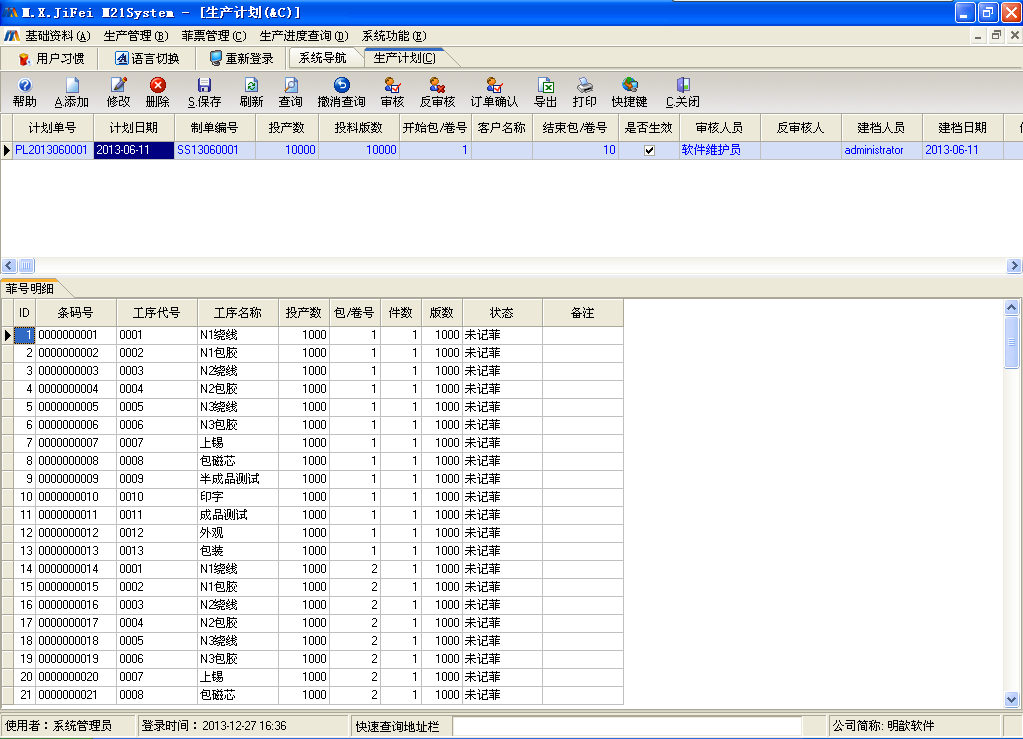

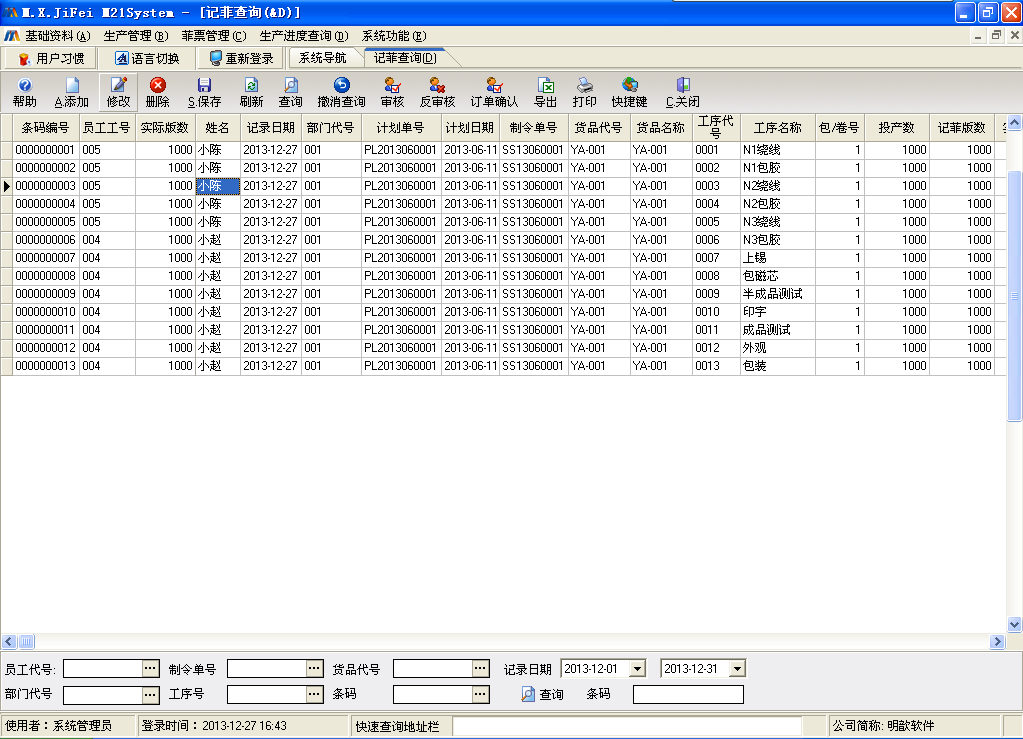

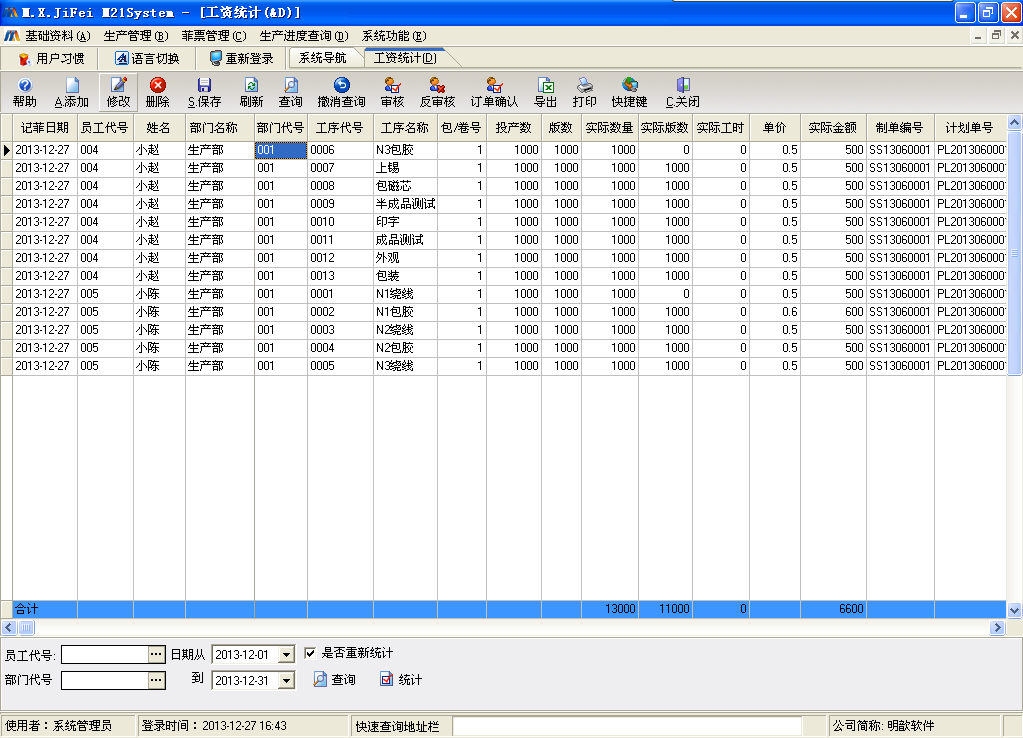

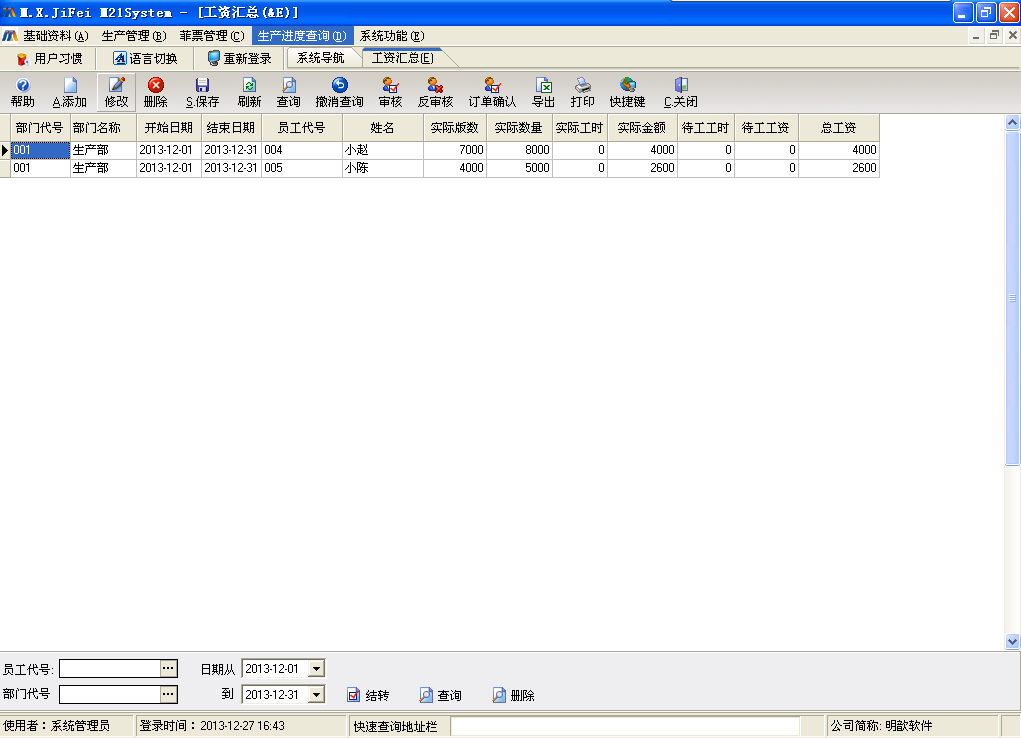

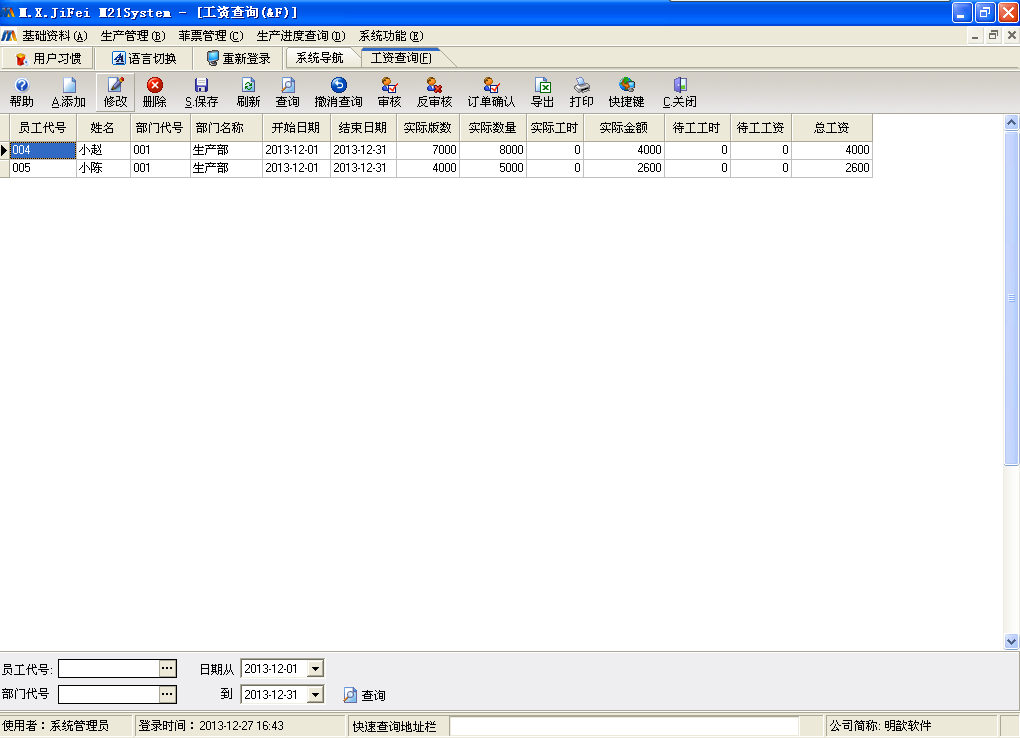

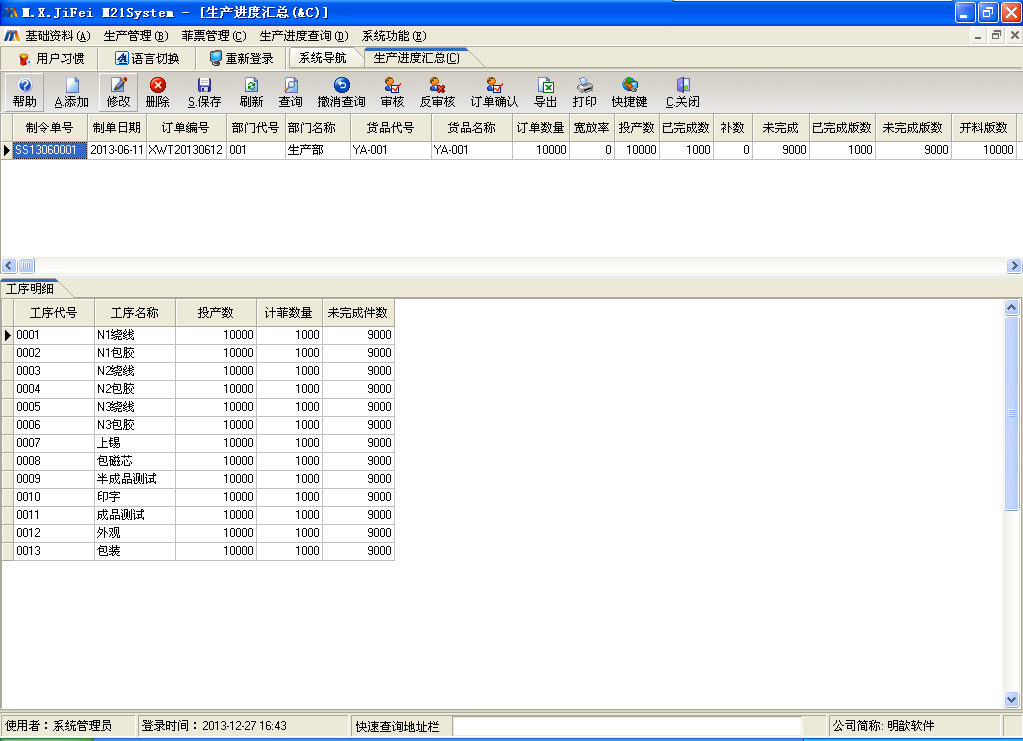

The "Mingxin M21A Production Process Scanning System" is a refined production scanning code management system that uses "QR codes" as a carrier to strengthen the precise management of the quantity of orders made. Each order is made into a standardized quantity of QR codes, and each employee completes piece count statistics by scanning the code with their mobile phone. Employees can check their daily production and piece count amount through their mobile phones at any time, allowing the enterprise to fully grasp the status of each production process, It is a new tool for enterprise management! Version Description: Single player single player version/Multi player network version! Suitable industries: Suitable for various industries such as electronics, toys, glass, machinery, furniture, pharmaceuticals, chemicals, plastics, hardware, molds, gifts, boutiques, electroplating, computers, food, trading companies, etc! System functional modules: initialization information, production document preparation, production planning, process management, scanning and piece counting management, (timing, single person piece counting, collective piece counting), production progress management, personnel management, salary management, report center! Introduction to system features and functions: 1. Each employee uses their job number as the standard code (the job number generates a QR code), and each process employee uses their mobile phone to scan and count pieces! 2. The production personnel set the corresponding process and unit price for each item number, set the standard quantity for each box, and each employee can query the quantity of goods in real-time! 3. The work ticket can be calculated by the statistician with or without the unit price set for the employee! 4. Each employee can scan multiple processes, and multiple people can scan the code for the same process! 5. The workshop clerk can change the process/quantity/or scan the wrong process to make changes! 6. You can set machine limit administrators to check the progress of each order and modify the number of incorrect scanning processes on site! 7. Production personnel can set up the inspection (packaging) process, and the salary can be calculated based on the inspection (packaging) process or the actual quantity of each process. There are two calculation methods to choose from! 8. Production personnel can set the number of orders to be scanned for this model number, and the number exceeded by scanning cannot be scanned again! |

|